Meltio Robotic Integration

Meltio Engine Specifications

Dimensions (W*D*H):

390*650*1000mm

Print Envelope (X*Y*Z):

inherent to motion system

Weight:

142kg

Laser Power:

1200W

Laser Type:

multiple 200W Direct Diode Lasers

Laser Wavelength:

976nm

Process Control:

closed-loop, laser and wire modulation

Power Input:

208/230V Single Phase or 400V Three Phase

Power Consumption:

2-5kW peak depending on selected options

Wire Feeds:

from one K300 spool up to two external wire drums

Wire Feedstock:

0.8-1.2mm wire diamater

Powder Feeds:

external plug and play powder feeders

Powder Feedstock:

45 to 90um particle size

Cooling:

water-cooled chiller included

- Description

- Reviews (0)

Description

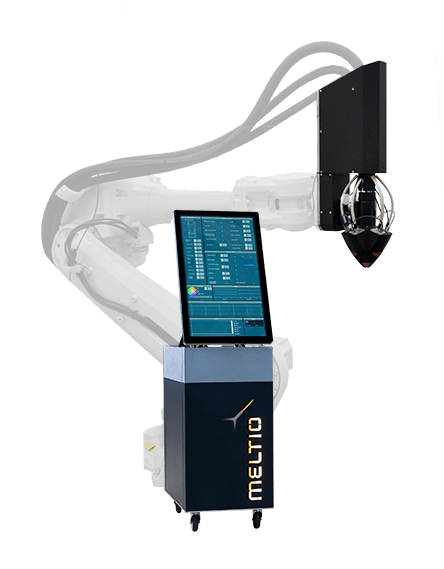

Meltio Engine Robot Integration

Turn a robot arm into a metal 3D printing system with no inherent size constraints. The Meltio Engine Robot Integration is the perfect platform for large and complex 3D printing, repair, cladding and feature addition.

Unlock geometry freedom in part size and complexity by integrating Meltio with a Robotic Arm. The

cost-effective solution for large metal part manufacturing

Robot Integration Hardware

Unconstrained metal 3D printing. Mounting hardware for the deposition head, and

related electronic sensors in robotic applications.

Reviews

There are no reviews yet.